Bringing Steel to Life

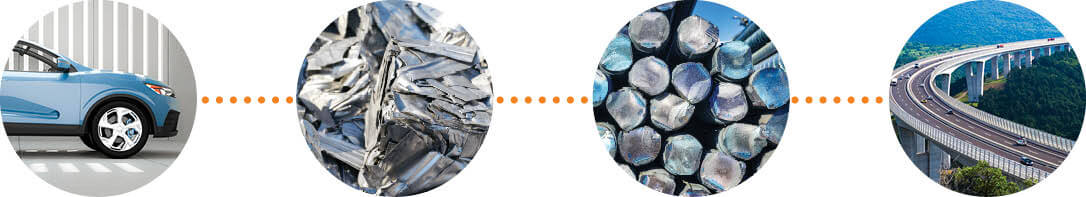

CMC’s steel products and construction solutions are essential in the building of critical infrastructure and other structures. Our products can be found everywhere, from the places we live and work, to the roads we travel and to the infrastructure that powers our homes and businesses.

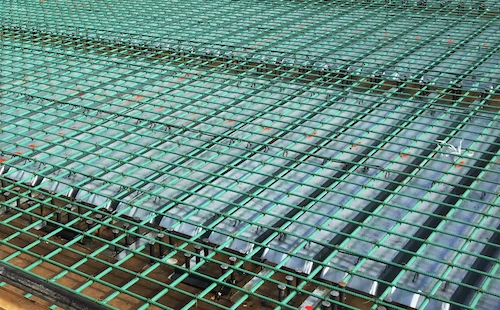

Our business model is inherently sustainable. Each year, we gather, sort, upgrade and transform over 16 billion pounds of scrap metal into high-quality steel products at facilities that produce some of the greenest steel in the world. Our geogrid products provide a number of sustainability benefits including reduced material and transportation requirements and longer asset life, helping our customers meet their sustainability goals.