Why it Matters

CMC has valued product innovation and sustainability since the foundation of the company. From the start, we have cared about the impact our operations have on the environment and have proven to be successful in finding opportunities to strengthen our business by investing in environmentally beneficial initiatives. We take pride in being a forward thinker and an innovator in the steel industry and are proud of the products we make and the role they perform in society. Through innovation, we are discovering new ways to improve the quality of our products and are leading the development of sustainable steel products

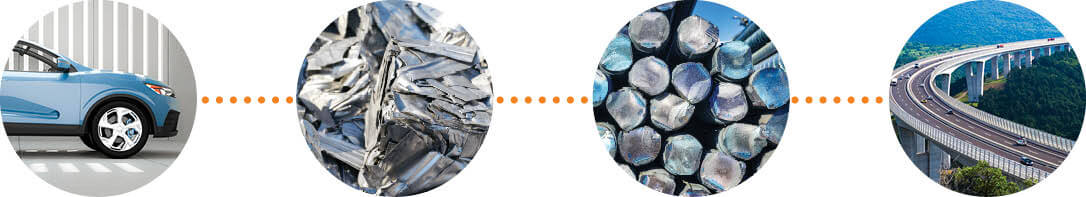

Our robust recycling strategy keeps metals in the circular economy instead of going to landfills.